Galvanized corrugated iron factories contribute significantly to the economy by providing jobs and stimulating local markets. These factories often employ a range of skilled and unskilled workers, creating job opportunities in engineering, manufacturing, and logistics. Additionally, they stimulate other sectors, such as supply chain and retail, by providing essential materials for construction and manufacturing projects.

Galvanized iron steel sheet factories are a cornerstone of modern manufacturing, providing materials that are integral to numerous industries. Through advanced production techniques, a commitment to sustainability, and a focus on quality, these factories play a crucial role in supplying robust and reliable materials that meet the evolving needs of the global market. As industries continue to innovate and grow, the significance of galvanized steel sheets will undoubtedly remain prominent, reaffirming their place in contemporary manufacturing.

When it comes to enhancing the aesthetics of outdoor spaces, large metal planter boxes have become increasingly popular among gardeners, landscapers, and homeowners alike. These stylish and durable planters not only provide a modern touch to gardens, patios, and balconies but also offer practicality for growing a variety of plants. With the growing demand for these planters, the market for large metal planter box suppliers has expanded significantly. However, selecting the right supplier is crucial for ensuring quality, stability, and an appealing design that matches your landscaping vision.

When it comes to the construction and renovation of buildings, roofing is one of the most critical aspects that cannot be overlooked. Roofing materials, including sheets, play a vital role in ensuring the structural integrity, insulation, and aesthetics of a building. As architects, builders, and homeowners look for efficient ways to design and install roofs, the importance of roof sheet calculator manufacturers has become increasingly evident.

Kina har i løpet av de siste tiårene opplevd en imponerende økonomisk vekst, som har gjort det til en av verdens største produsenter og leverandører av byggevarer. Et av de mest interessante produktene som har steget frem i denne sektoren, er magnesium oksid (MGO) takplater. Disse platene har blitt populære, ikke bare i hjemmemarkedet, men også blant internasjonale kjøpere, inkludert europeiske land som Norge.

In summary, soldering tin plate manufacturers play a crucial role in the electronics sector by providing high-quality materials that ensure the reliability and efficiency of electronic devices. As technology continues to advance, the industry is witnessing significant innovations in manufacturing processes, underscoring the importance of quality and sustainability. By focusing on these areas, soldering tin plate manufacturers not only enhance their competitive edge but also contribute to the overall progress of technology, paving the way for a more connected and efficient future. The ongoing evolution of this sector will undoubtedly shape the next generation of electronic products, reinforcing the essential role these manufacturers play in our modern world.

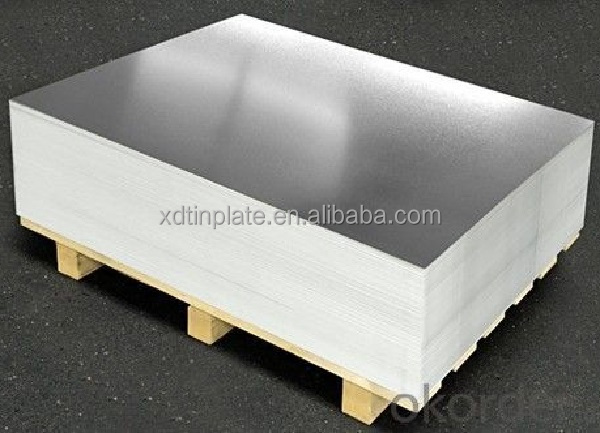

Tin plate is a thin sheet of steel that has been coated with tin. This coating is vital for protecting the underlying steel from corrosion, enhancing the longevity of products made from it. The popularity of tin plate in the packaging industry is attributed to its lightweight nature, resistance to oxidation, and ability to be easily formed into various shapes. Additionally, tin provides a non-toxic coating, making it an ideal choice for food-grade applications.

En resumen, los fabricantes de tapas para tejas corrugadas son una parte esencial de la industria de la construcción. Al elegir un proveedor, es fundamental considerar la calidad de los materiales, la innovación, la personalización y la reputación de la empresa. Con la combinación adecuada de estos elementos, se pueden garantizar techos duraderos y estéticamente agradables que satisfagan las exigencias de los proyectos modernos.

Prayer tin boxes are more than just decorative items; they have a profound significance in many cultural and spiritual contexts. Traditionally, they serve as a personalized place for believers to write down their prayers or intentions. This practice encourages individuals to focus their thoughts and cultivate a deeper spiritual connection. Additionally, prayer tin boxes make excellent gifts for special occasions, such as weddings, graduations, or religious ceremonies, symbolizing goodwill and the sharing of blessings.

Moreover, Graze the Roof is not limited to the creation of music but extends to the experience of listening as well. For listeners, the act of immersing oneself in a piece of music can lead to profound moments of revelation and connection. The melodies that drift seamlessly into our consciousness can lift our spirits, calm our anxieties, or ignite our passions. It’s as if the listener, too, is reaching for that rooftop, transcending everyday life and its challenges to tap into something ethereal.

In conclusion, roof panel sheet metal manufacturers are integral to the future of modern architecture. As the industry moves toward more sustainable and efficient building practices, their role becomes increasingly pivotal. By producing durable, aesthetically pleasing, and energy-efficient roofing solutions, these manufacturers contribute significantly to the construction landscape, helping to shape the buildings of tomorrow while addressing the environmental challenges of today. With continued innovation and collaboration, it is clear that the influence of roof panel sheet metal manufacturers will persist—making them key players in the transformative journey of the architectural world.

Despite their many advantages, there are also challenges to the widespread adoption of PHEVs. The initial purchase cost can be higher than that of traditional vehicles, which may deter some potential buyers. Furthermore, to maximize their environmental benefits, users must be willing to regularly charge their vehicles and utilize electric power whenever possible. Additionally, while PHEVs are generally more efficient than conventional vehicles, they can still contribute to emissions when operating in gasoline mode.

The process of galvanization typically involves hot-dipping, where steel or iron is submerged in molten zinc. This method creates a thick, metallurgically bonded layer of zinc and iron, resulting in a robust protective coating. An alternative method, known as electro-galvanization, uses electrical current to deposit zinc onto the metal surface, creating a thinner layer of protection.